For twenty years, the

UNI EN 1335-1:2000 standard has established the dimensional requirements for office chairs, dividing them into three types (A, B and C) according to their degree of adjustability and therefore adaptability to the size of the specific user, so as to allow compliance with the requirements of Legislative Decree 81/2008.

As is now known, from October 2020 the

UNI EN 1335-1:2000 standard has been replaced by the

new edition UNI EN 1335-1:2020 “Dimensional requirements for office chairs” in which the requirement for height adjustment of armrests was made more stringent.

But how did the modification in the adjustable armrests requirement change the strength test results?

We have often wondered this since the publication of the new version. For the type A office chair, in fact, there has been a change from the 50 mm of height travel required by EN 1335-1:2000 to the current 100 mm; armrests must also be adjustable in width (clear distance between the armrests).

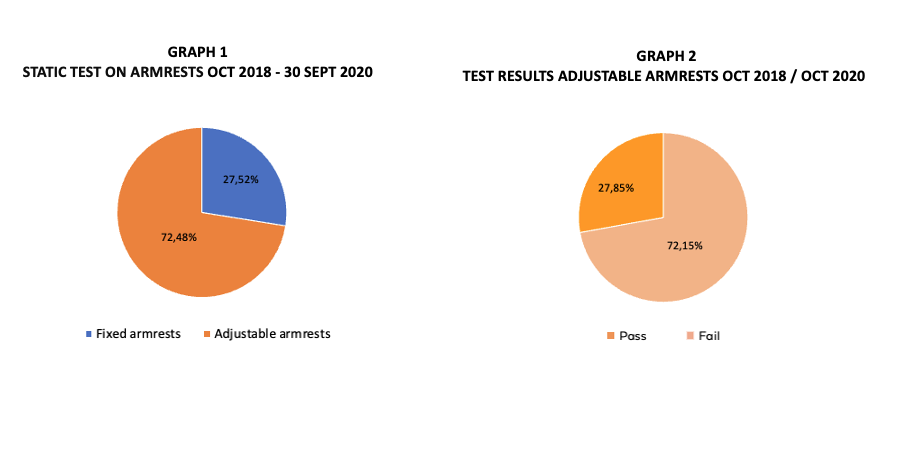

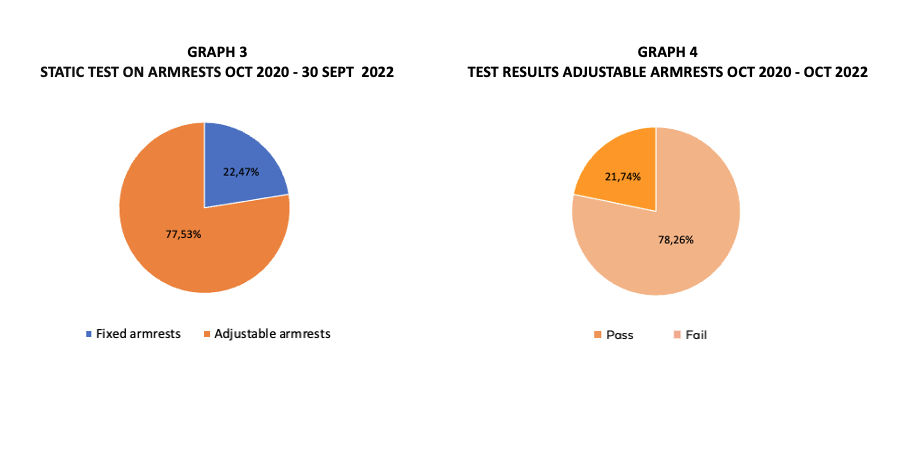

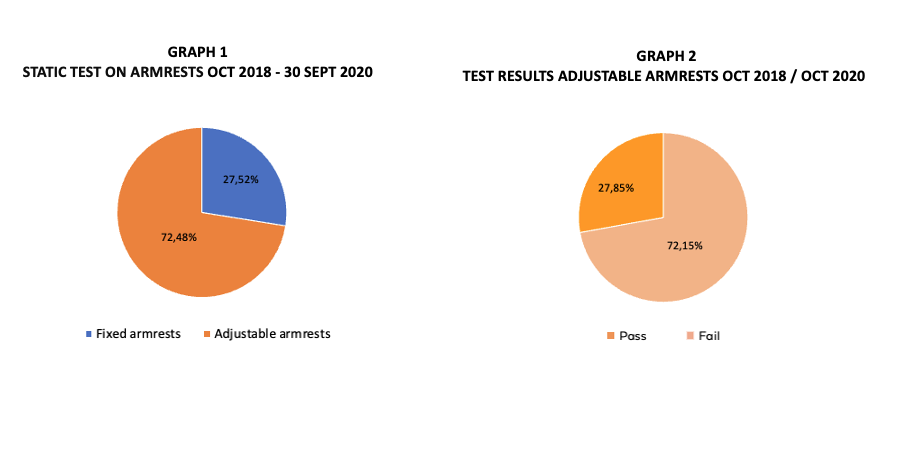

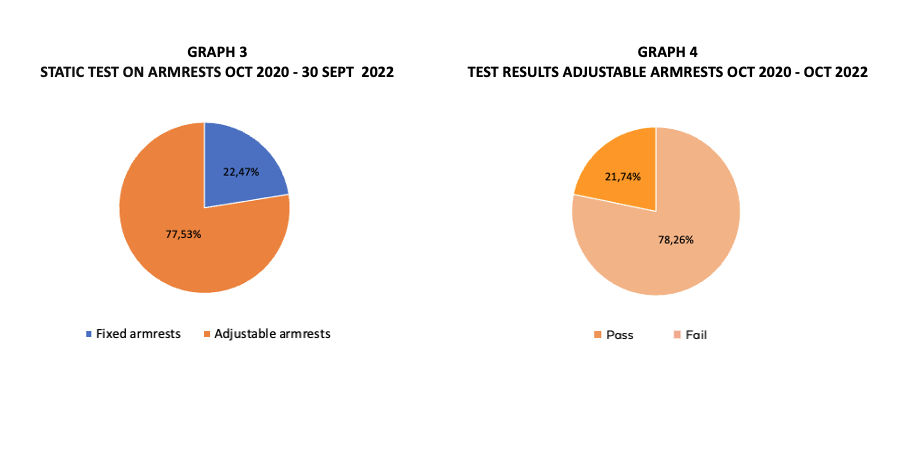

As these changes could be expected to affect the resistance of the armrests to static load, since this test performed with the armrests adjusted to their maximum height and maximum width, we therefore would like to analyze all the static load tests on the armrests carried out in the two years prior the publication of the new standard (October 2018 / October 2020 - 30 September 2020) with the tests performed in the two years following the change (October 2020 / October 2022) and these are the results:

The choice of adjustable armrests instead of the fixed ones increased by 5 percentage points. This happen probably because, for type A seats, the armrests, if present, shall be adjustable.

Looking at the results, however, it can be noticed that the failed tests have slightly decreased (from 27.85% to 21.74%), even though he adjustment requirement of the armrests has doubled.

The numbers of tests analyzed are slightly different (109 total tests in the two-year period 2018/20 and 178 total tests in the two-year period 2020/22) and therefore we also wanted to verify the percentage of positive and negative results for the same number of samples.

From the graph it can be seen that the result between failed and passed tests is almost aligned in the two periods analyzed.

Final considerations:

At the time being, the number of breakages highlighted during the static load test on the armrests have aligned with the data detected before the change in requirement; great credit to the manufacturers of armrests, who have been able to make the right changes to obtain a positive result.

Per info:

For twenty years, the UNI EN 1335-1:2000 standard has established the dimensional requirements for office chairs, dividing them into three types (A, B and C) according to their degree of adjustability and therefore adaptability to the size of the specific user, so as to allow compliance with the requirements of Legislative Decree 81/2008.

For twenty years, the UNI EN 1335-1:2000 standard has established the dimensional requirements for office chairs, dividing them into three types (A, B and C) according to their degree of adjustability and therefore adaptability to the size of the specific user, so as to allow compliance with the requirements of Legislative Decree 81/2008.