CATAS has recently equipped itself with a new device, an X-ray fluorescence spectrophotometer.

The energy-dispersive X-ray fluorescence technology (ED-XRF) is one of the simplest, most accurate and economical methods of elemental analysis for many types of materials.

It is a non-destructive and reliable technique, suitable for solid, liquid and powder samples and does not require any special sample preparation as it measures the fluorescence radiation emitted from the analyzed surface when it is hit by high energy X-rays, without any contact with the sample to be analyzed.

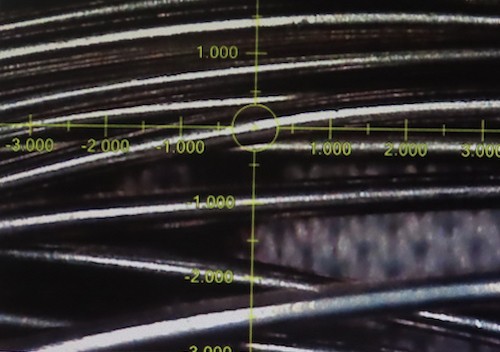

The choice was made to meet the laboratory's need to measure the thickness of metallic coatings in samples to be submitted to corrosion tests in salt spray, without having to carry out long and laborious preparations of the specimens. With this instrument, in fact, accurate measurements of chromium plating, nickel plating, galvanizing, etc. can be obtained in just a few seconds, whereas before, to obtain the same result, it was necessary to use the optical microscope and then carry out very accurate sections of the material to be measured with a considerable loss of time and energy.

The technique has also proved to be very useful in the qualitative research of numerous elements on the most varied surfaces, for example wood, paints, plastics, paper, on compacted powders and even on aqueous fluids. This will allow to perform preliminary screening analyzes, such as the research of toxic metals and brominated compounds in materials subject to RoHS (Directive 2002/95 / CE); or it will constitute an additional opportunity in the case of analysis of superficial defects (inclusions, stains, etc.).