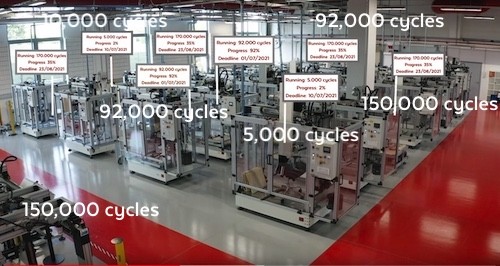

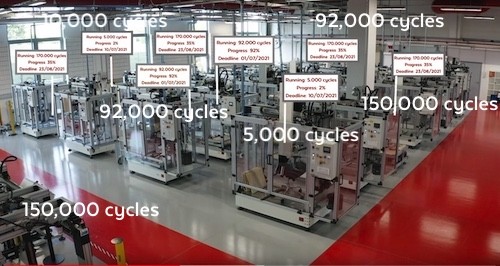

Today there are over a hundred (

109 to be precise) CATAS test working stations, operating both in the San Giovanni al Natisone (UD) site and in the Lissone one, in Brianza region, interconnected and interfaced in real time with the laboratory management system. Of course, we are talking about the test equipment that provide for

repeated fatigue cycles, up to 200,000, but even more if the customer requests it, and extended completion times, even up to

4 weeks of continuous work. If we multiplied all these numbers by the quantity of furniture samples that every year are sent to our 2 testing sites, about

5,000 between Udine and Lissone, make it clear that the digital transition has been an important opportunity for the CATAS development in terms of optimization and control of the progress of the lab operational activities.

Whether they are the tests in progress, at the CATAS sites in Friuli or in Brianza, the essential remains: once the test has been set up and started, the progress of the order is promptly monitored not only on the machine display but also remotely by the desks dedicated to the monitoring.

An

ad-hoc digital layout developed allows us to view (since at a first glance!) the state of use and availability of each equipment. A

dedicated web platform reports exactly which sample, on which working station and how long it will be still tested.

All these are data that become a working tool for our activities in terms of the optimization of the testing schedule and of the use of the machines, in terms of

information about the service in progress, from the completion rate, up to the expected ending date.

The digital reality of CATAS does not only concern the test environment, but also the processes upstream and downstream of the line. The

myCATAS web area, an online tool dedicated to the all CATAS subscriber customers (Italian and not), which allows them to be connected, on their own and digitally, has already been in production since 2015. At present, we have registered about 1,000 users who can access the continuously up-to-date archive of their test reports and the CATAS Academy seminars and webinars at any time, and over 4,000 orders sent and managed each year via the web.

In short: our roadmap towards the digitalization is already tracked and it is now at its first full capacity.

These are just some of the first tangible results of a development process that CATAS has been undertaking for some time. The primary goal is always the attention to the customer and to his needs of efficiency, promptness and direct contact with our Institute.

And we are already working on new future steps: a better tracking of samples, the analysis of all the collected data (about categories, timing and schedules of the tests, but also the frequency of maintenance and monitoring of the performance of the machines) and their transformation into useful information for an ever better management of the

timing and methods of our work.

Stay tuned to find out more!

CATAS Staff.

Today there are over a hundred (109 to be precise) CATAS test working stations, operating both in the San Giovanni al Natisone (UD) site and in the Lissone one, in Brianza region, interconnected and interfaced in real time with the laboratory management system. Of course, we are talking about the test equipment that provide for repeated fatigue cycles, up to 200,000, but even more if the customer requests it, and extended completion times, even up to 4 weeks of continuous work. If we multiplied all these numbers by the quantity of furniture samples that every year are sent to our 2 testing sites, about 5,000 between Udine and Lissone, make it clear that the digital transition has been an important opportunity for the CATAS development in terms of optimization and control of the progress of the lab operational activities.

Today there are over a hundred (109 to be precise) CATAS test working stations, operating both in the San Giovanni al Natisone (UD) site and in the Lissone one, in Brianza region, interconnected and interfaced in real time with the laboratory management system. Of course, we are talking about the test equipment that provide for repeated fatigue cycles, up to 200,000, but even more if the customer requests it, and extended completion times, even up to 4 weeks of continuous work. If we multiplied all these numbers by the quantity of furniture samples that every year are sent to our 2 testing sites, about 5,000 between Udine and Lissone, make it clear that the digital transition has been an important opportunity for the CATAS development in terms of optimization and control of the progress of the lab operational activities.